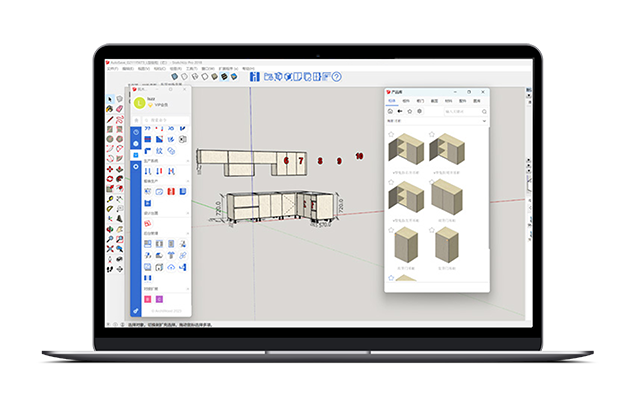

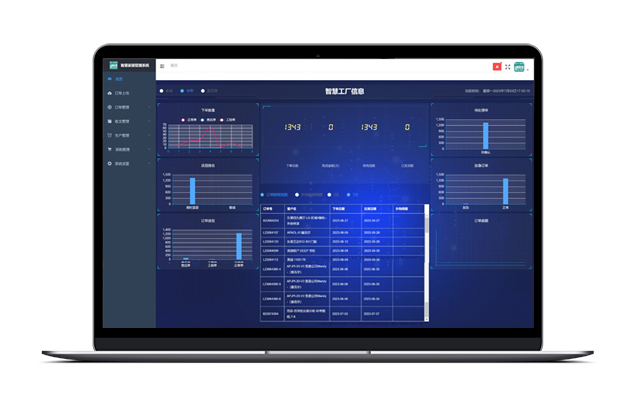

AIS Group is the Top 10 cabinetry manufacturer as OEM/ODM manufacturers that specialize in Custom Kitchen Cabinetry Works in South of China,offers a one-stop service from site measurement to installation with more than 22 years of experience . We committed to to Quality Assurance and guarantee a life-time warranty for all of our products.